Products & Services

Deep Drawn

Our Approach

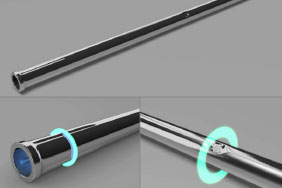

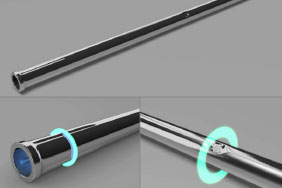

Deep drawing is a process which uses tensile forces to stretch metal to a cylindrical shape, these have been used across a wide range of industries from electronics, medical, cosmetic and other consumer products.

They have the advantage of being able to replace several components within a device or product with one formed part reducing assembly, time and material costs.

The critical feature of any deep drawn component is the ratio between the length and diameter, known as the limiting drawing ratio (LDR).

Advanex can currently produce components well in excess of forty times length as opposed to diameter (LDR 40:1) but we are constantly challenging our technology and are pushing the boundaries.

The forming process provides several advantages over machining or other alternative production methods as additional features can be produced without the need for secondary.

Deep drawn metal forming is particularly economical at high volumes, where reduced processing cost significantly lowers piece-part cost. At smaller volumes, the process can be more economical than progressive die stamping due to reduced tool costs.

From a functional standpoint, deep drawn metal forming produces high strength and light weight parts as well as incorporating shapes and forms impossible with some other manufacturing processes.

Advanex uses one production process to complete complex forms with LDR of 40:1

Join our global partnerships